The smart way to control maritime vessels: data-driven.

With besecke, you can keep an eye on everything across the board. And have all the controls at your fingertips.

The entire 10.000 m2

on one dashboard

We ![]()

![]()

![]()

make your

vessels more efficient , by ensuring that they only consume the energy that is really needed. Thanks to smart automation

vessels more efficient , by ensuring that they only consume the energy that is really needed. Thanks to smart automation .

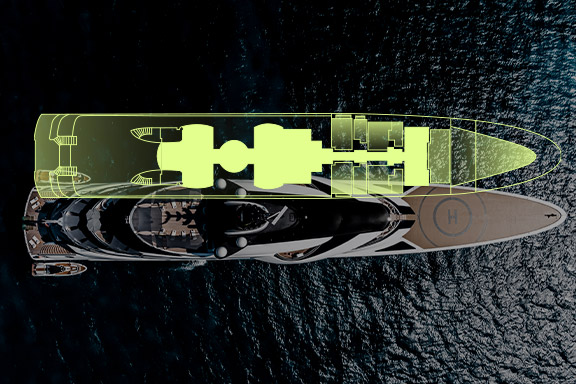

Yachts

Our power distribution systems and automation solutions meet complex requirements of a modern mega yacht. Due to our long-lasting expertise, we became market leader in this segment and we are pleased that already eight of the 13 largest yachts in the world rely on our solutions.

Authority ships and naval vessels

Our connected software products and intelligent power distribution systems make every project smarter and more powerful. Due to a modular design, our solutions can be used on a 20m coast guard boat as well as on a 100m research vessel.

Smart Solutions: Our Services and Systems

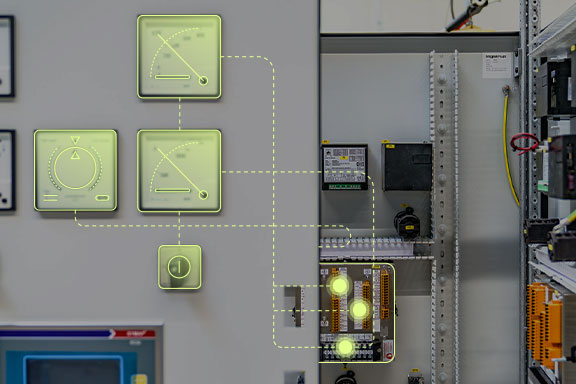

AllViu - The visualisation platform

beVISION

Visualization System for Intuitive Operation and Notification

Scalable alarm, monitoring & control system for up to 20,000 I/O's.

beSECUR

Security solution for mega yachts

Our comprehensive security solution for mega yachts with sophisticated monitoring of the ship's exterior, interior and environment.

beWATCH

BNWAS - Bridge Navigational Watch Alarm System

Modularly designed and fully integrable bridge watch alarm system.

beSAFE

Vessel Safety Station

System for clear indication of all fire zones, fire detectors and dampers as well as closure display of ext. doors and hatches.

beMOTION

Helicopter approach solution

Individually configurable solution for visualization of roll, pitch and heel as well as for switching the helicopter landing lights.

Energy distribution and energy systems

Maritime Power Distribution Solutions

Design and manufacturing of main switchboards, emergency switchboards, Motor Control Center (MCC) as well as power distribution cabinets.

MarESiS

Maritime Energy Simulation System

Maritime energy simulation for optimized design of electrical and hybrid ship systems.